A perfume can smell amazing, but a bad spray can destroy the first impression. I have seen many brands lose repeat buyers because the spray feels wet, uneven, or “cheap.”

A perfume atomizer is a spray system that turns liquid perfume into a fine mist using a pump, a dip tube, and a micro-nozzle. When you press the actuator, the pump builds pressure and forces perfume through a tiny channel, so the liquid breaks into small droplets.

When I talk with new perfume brand owners, most of them start with bottle shape1. I understand that. The bottle is the “face.” But the atomizer2 is the “handshake.” It is the first physical contact the customer feels. That is why I always explain the atomizer2 in simple terms, so you can choose parts with fewer mistakes and less after-sales risk.

Why do brands and users prefer an atomizer over an open bottle?

A strong formula cannot fix a messy application. I tested samples where the scent was great, but the spray made big drops and left wet marks on clothes.

An atomizer gives controlled dosing and a smoother feel. It spreads the scent more evenly on skin and fabric, so the fragrance performs better.

Better dosing and less waste

When I compare an atomizer with an open-neck bottle, the main difference is repeatability3. People like “one press is one press.” Stable dose per spray also reduces complaints like “it runs out too fast,” because the output stays consistent when the pump is correct.

Cleaner use and safer shipping

An open bottle can spill easily. A spray system reduces direct contact with liquid and is more travel friendly. From a logistics view, a good crimp and a good cap also reduce leakage risk during long shipping routes.

Brand experience and price perception

Small brands often compete on value. But value does not mean “cheap feel.” A smooth press, a clear spring return, and a fine mist can lift the whole product image.

| Application type | User control | Spill risk | Dose consistency | Common use case |

|---|---|---|---|---|

| Atomizer spray | High | Low | High | Daily wear, gifting |

| Dab-on (roller/dabber) | Medium | Medium | Medium | Oils, small vials |

| Open neck (no applicator) | Low | High | Low | Lab samples, refills |

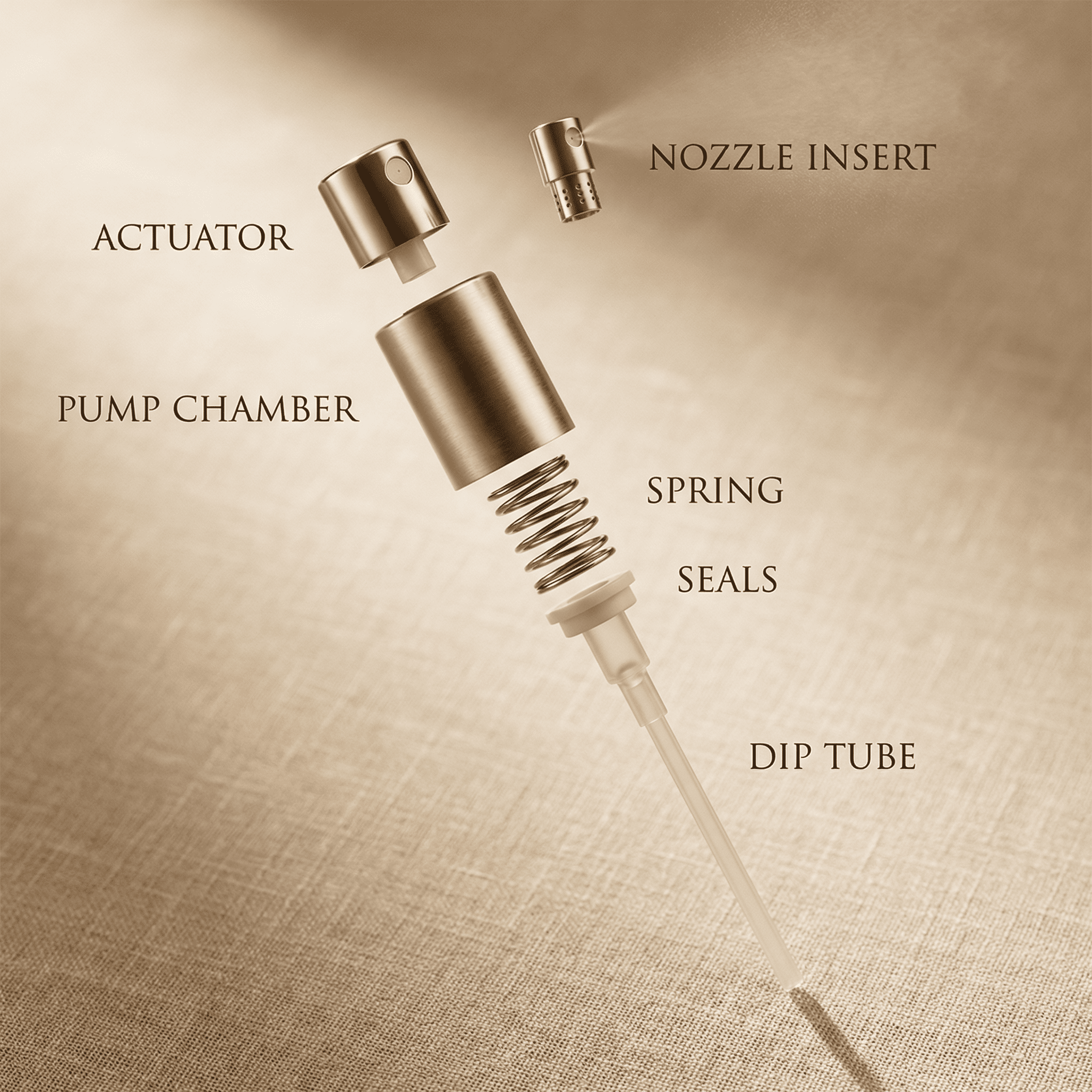

What parts make up a perfume atomizer?

Many people call the whole top “the atomizer,” but it is a system of parts. If one part is weak, the mist becomes unstable.

A typical atomizer includes an actuator, a pump chamber, a spring, seals, a dip tube, and a nozzle insert. Each part affects droplet size4, spray angle, and leakage control.

Actuator (the button you press)

The actuator shape affects comfort and spray direction. The inside channel must match the pump stem well. If the fit is loose, spray can shift or feel unstable.

Pump and spring (the pressure maker)

The pump is the heart. When you press, the chamber creates pressure and pushes liquid forward. The spring controls return and press rhythm. Spring material and strength matter, especially when the formula has heavy oils or special additives.

Gasket and seals (the leak and pressure guards)

Seals stop air leaks and liquid leaks. If materials are not compatible with the formula, they can swell or deform. Then pressure drops, and the spray can turn from fine mist to spitting droplets.

Dip tube (the liquid path)

Tube length must match the bottle. Too long and it bends. Too short and it leaves perfume unused at the bottom. Tube diameter also affects refill speed after each press.

| Part | Main job | What can go wrong | What I check first |

|---|---|---|---|

| Actuator | Comfort + direction | Loose fit, crooked spray | Stem match + alignment |

| Pump chamber | Builds pressure | Weak mist, hard priming | Dose spec + build quality |

| Spring | Return + stability | Soft feel, slow return | Material + strength |

| Seals/gasket | Prevent leaks + keep pressure | Leaks, spitting | Material compatibility |

| Dip tube | Feeds liquid | Poor pickup, bubbles | Length + clean cut |

How does an atomizer actually create a fine mist?

Some customers ask if this is “magic.” It is not. It is pressure plus tight tolerances. Small channels and controlled flow turn liquid into droplets.

An atomizer creates a fine mist by pressurizing perfume in a pump chamber and forcing it through a micro-nozzle. The nozzle shapes the flow so it breaks into small droplets and sprays in a cone.

Step-by-step: what happens when I press?

- I press the actuator

- The pump chamber moves and the spring compresses

- A valve system controls one-way flow

- Pressure pushes liquid toward the nozzle

- The nozzle insert forces liquid through a tiny opening

- The stream breaks into droplets and becomes a mist cone

This is why quality control matters. If the nozzle hole is inconsistent, droplet size changes. If a seal leaks air, pressure drops. If the dip tube pulls bubbles, the spray can cough or spit.

Droplet size, spray angle, and “wet spray”

When customers say “wet,” it usually means droplets are too large. Large droplets often come from low pressure, wrong nozzle design, or poor fit between parts. A good atomizer gives small droplets, a stable cone, and a clean stop when I release.

My field method: 500–800 press compatibility test (close to “finishing one bottle”)

When I help a perfume brand test an atomizer with their own formula, I never judge it by just a few sprays. I care about one thing: can this atomizer stay stable across the real life of the bottle?

That is why I recommend a 500–800 press compatibility test. This range is not random. It depends on the dose (output) per spray.

Here is a simple example: a 100 ml perfume paired with a 0.12 cc (0.12 ml) atomizer usually needs around 800 presses to use up the bottle.

Let’s calculate it clearly:

- 100 ml ÷ 0.12 ml per press = 833.33 presses

- In real use, that is roughly 800+ presses

This is the reason I like to test up to 800 presses. It is close to the customer’s real usage cycle. If the atomizer stays fine through this test, it strongly suggests the materials and structure are compatible with the perfume.

During the 500–800 press test, I focus on three checks:

- Mist shape: Does it stay a fine and even mist from the first presses to the last?

- Press feel: Does it become harder to press? Does the spring return slower?

- Sealing and leakage: Do we see oiling, seepage, or air bubbles that cause unstable spray?

I learned this from real cases. Some clients make formulas that are more viscous because they use more fragrance oil. At the beginning, the spray looks normal. But after hundreds of presses, the spring and the sealing plug can deform after long contact with perfume and alcohol. When pressure becomes unstable, the mist can turn into water-like droplets. Customers will think the whole perfume is defective, not just the pump.

So for me, 500–800 presses is not “over-testing.” It is a realistic filter. It helps a brand find risks before launch, not after customers complain.

| What I observe in 500–800 presses | What it tells me | What it can lead to |

|---|---|---|

| Fine mist stays stable | Materials + structure are stable | Strong compatibility |

| Mist becomes wet or droplet-like | Pressure/nozzle losing control | Seal deformation, spring fatigue, clogging |

| Press becomes harder over time | Flow resistance rising | Formula too viscous, channel too narrow |

| Spray becomes inconsistent | Valve or feed instability | Air bubbles, valve sealing issue |

| Leakage around pump/collar | Sealing/crimp failure | Material mismatch or assembly issue |

My second insight: why late failure damages a perfume brand more

I always say this directly: if the atomizer breaks after the customer has used the perfume for a while, the damage is bigger.

Customers do not separate “sprayer issue” from “perfume issue.” They will say, “this perfume is bad.” On e-commerce, one negative review can reduce conversions fast.

Then comes operations. Recalls and replacements are not just parts cost. They are labor, customer service time, packing, shipping, and tracking. For a small team, this is heavy. It can also slow down new launches because your team is busy fixing old problems.

So I believe compatibility testing must happen before a new formula goes to market. I prefer to solve the risk in sampling, not in after-sales.

| Risk if atomizer fails after delivery | What it causes | What I do before launch |

|---|---|---|

| Negative reviews | Lower trust and conversion | Press test + mist check |

| Refunds/replacements | Direct money loss | Confirm seal + spring stability |

| Recall workload | Big time cost for small teams | Test with real formula, not water |

| Brand image damage | Hard to rebuild | Choose stable spec + supplier |

How do I choose and customize an atomizer for my perfume brand?

A new brand can lose money by choosing parts only by looks. I have seen beautiful caps paired with weak pumps, and the customer experience5 collapses.

I choose an atomizer by matching dose, neck finish, and materials to the formula and brand positioning. Then I customize the look with color, frosting, metallization, decals, and caps while keeping performance stable.

Match performance to your formula and use case

I start with dose per spray and mist fineness. A “soft daily mist” can use a lower dose. A “bold signature spray” can use a higher dose. Then I check if the formula is normal or more viscous, because viscosity affects sealing and flow.

Fit to bottle neck and assembly method

Many perfume bottles use crimp necks. Crimp quality affects leakage and wobble. If the crimp is loose, the pump moves. If it is too tight, parts can deform. I control this with clear specs and sampling.

Samples from Hongyan Glass (welcome to inquire)

To make testing easier, Hongyan Glass provides atomizer samples in different doses and different fine-mist levels. You can test with your real formula, run the 500–800 press test, and then choose the safest option before bulk production.

We also offer 500+ in-stock perfume glass bottle designs, and we support spray color, frosting, gilding, and decals. We provide a one-stop perfume packaging service, and we support 3D sampling for new glass bottle designs. If you want good value and low MOQ, starting with samples is the most practical path. Feel free to ask for a quote.

| What I can provide | Why it helps your brand | Best time to use it |

|---|---|---|

| Different spray doses | Match positioning + feel | Formula final stage |

| Different mist fineness levels | Reduce “wet spray” complaints | Pre-launch testing |

| 500+ in-stock bottles | Lower MOQ + faster launch | First product launch |

| Custom decoration processes | Stronger brand look | After direction is clear |

| 3D sampling for new bottles | Lower trial cost | When you want a unique bottle |

Conclusion

I treat atomizer testing as brand protection, because late failure triggers reviews and heavy replacement costs, so I prefer a 500–800 press test before launch.

-

Exploring the impact of bottle shape on branding can enhance your marketing strategy and attract more customers. ↩

-

Understanding the role of an atomizer can help you make informed choices in your perfume design, ensuring a better customer experience. ↩ ↩

-

Understanding repeatability can enhance your product's reliability and

repurtation ↩ -

Exploring droplet size can enhance your knowledge of spray technology and its impact on efficiency. ↩

-

Understanding the elements that shape customer experience can help brands enhance satisfaction and loyalty. ↩